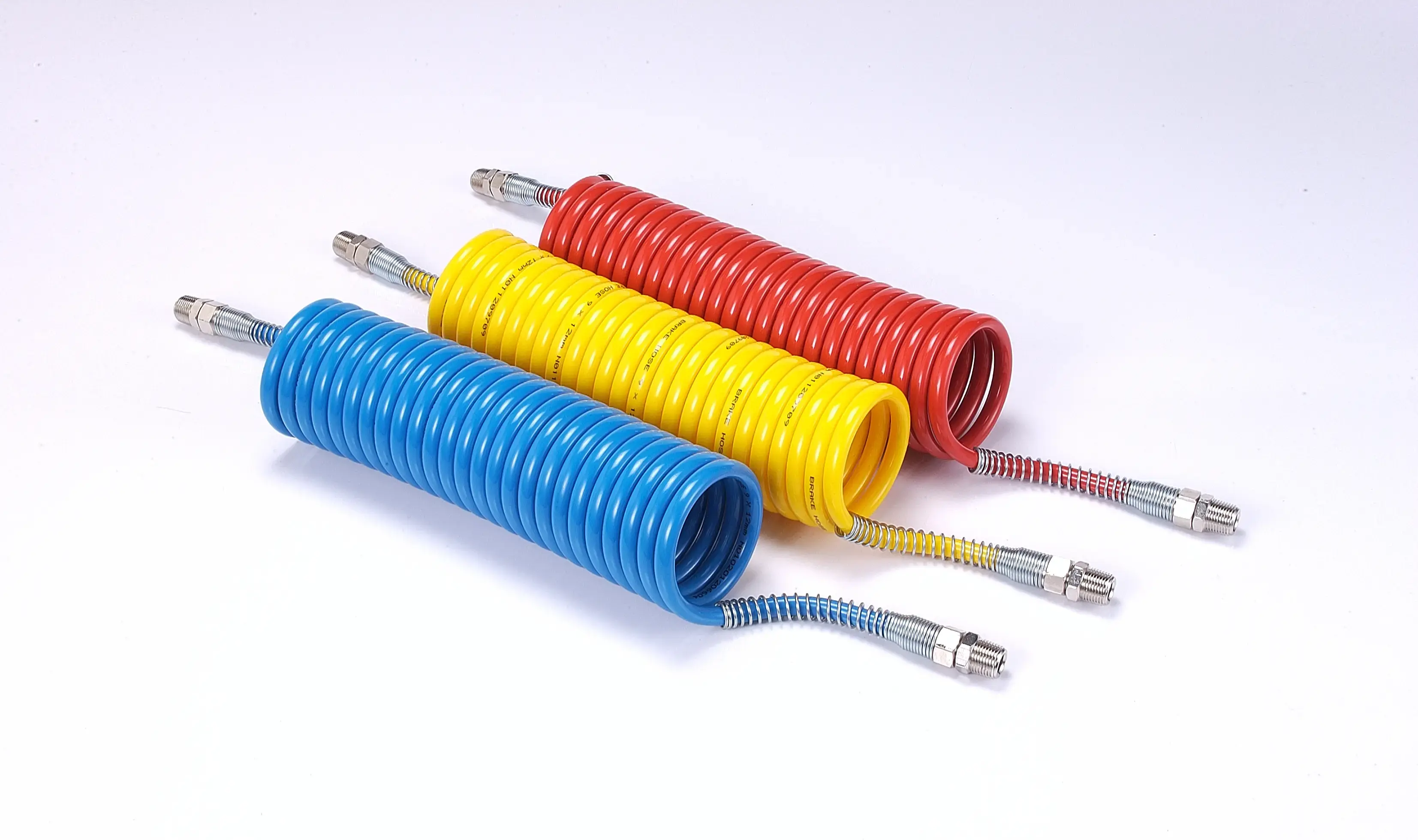

A trailer tube is a type of flexible and durable tube commonly used on the trailers of trucks and semi-trailers. These tubes are primarily used to ensure that loads are securely fastened during transport. Trailer tubes can often have functions such as transporting air, liquid, or vacuum, and are designed to be highpressure resistant, long-lasting, and resistant to UV rays.

Trailer tubes are usually made of polymer materials and may contain rubber or plastic components. PA12 and Polyurethane raw materials are the basic components of the trailer tube.

Connection fittings must be of high quality, impact-resistant brass material and nickel-plated on top. They are frequently used in air brake systems, fuel lines, and other transport needs in industrial vehicles. Their flexible structure makes them resistant to impacts,which makes them a preferred product in the transportation sector.

| Product code | External | Internal | Thickness | Tolerances | Coil Inside ID | W.P. at 23°C | B.P. at 23°C | Length | Usage Length | Available Colours | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BL | BU | YL | RD | GR | ||||||||||

| PA12RECOIL4060 | 6 mm | 4 mm | 1 mm | +- 0,1 mm | 35 mm | 29 bar | 87 bar | 5 - 7,5 - 10 - 15 - 20 m | 3,35 - 5 - 6,70 - 10 - 13,50 m | |||||

| PA12RECOIL4060 | 8 mm | 6 mm | 1 mm | +- 0,1 mm | 35 mm | 21 bar | 63 bar | 5 - 7,5 - 10 - 15 - 20 m | 3,35 - 5 - 6,70 - 10 - 13,50 m | |||||

| PA12RECOIL8010 | 10 mm | 8 mm | 1 mm | +- 0,1 mm | 70 mm | 16 bar | 48 bar | 5 - 7,5 - 10 - 15 - 20 m | 3,35 - 5 - 6,70 - 10 - 13,50 m | |||||

| PA12RECOIL9012 | 12 mm | 9 mm | 1,5 mm | +- 0,15 mm | 70 mm | 21 bar | 63 bar | 5 - 7,5 - 10 - 15 - 20 m | 3,35 - 5 - 6,70 - 10 - 13,50 m | |||||